Ultrasonic Carburetor Cleaning

So, you’re tired of gummed up carburetors, replacing them, or at the very least paying to have them cleaned. The problem with carburetors is that they are comparatively small and very complex.

This means to clean them properly there’s a lot of dis-assembly, cleaning, and reassembly to deal with. Not to mention the risk of breaking something during cleaning! Luckily there’s an alternative to either replacing or having your carbs cleaned professionally: ultrasonic cleaning!

Ultrasonic Cleaning – the Professional Carburetor Cleaning Technique

So the obvious question is, “What’s ultrasonic cleaning?” The simple answer is that ultrasonic cleaning uses high frequency sound waves to clean things at a microscopic level. But that doesn’t really tell us a whole lot about HOW the sound does the cleaning.

How Utrasonic Cleaning Works

What actually happens is a phenomenon knows as “cavitation.” Cavitation is the rapid formation and collapse of microscopic vacuum bubbles in a liquid caused by the previously mentioned sound waves.

When the sound waves shove these vacuum bubbles against the surface of the object being cleaned, they collapse. This collapse produces a lot of energy as the surrounding cleaning fluid rushes to fill the space the vacuum bubble once occupied. This results in a very powerful scrubbing action.

The scrubbing power is not only strong, but also very precise. Keep in mind these vacuum bubbles are microscopic! That means that your parts will be cleaned at a microscopic level, leaving them as pristine as they could possibly be. This is why ultrasonic cleaning is so popular in the medical and manufacturing industry, where even minute amounts of soil could have a huge impact.

Choosing Your Carb Cleaner

Ok, so you’ve decided that ultrasonic cleaning looks right for you. So how do you get started? First you need to ask yourself a few questions:

How big are my carburetors?

How many parts do I want to clean at once?

How quickly do I need the cleaning to be done?

What’s the soil load like on my carburetors, what soil is it?

The answers to these questions will dictate the size, and what accessories you need with your new carburetor cleaner. The first question is kind of a no-brainer. The size of your carburetor will dictate the size of the tank, and what kind of basket you will need.

For proper ultrasonic transmission, an ultrasonic unit needs about an inch of space from the bottom of the tank, to the bottom of the object being cleaned. To facilitate this, most users employ a mesh or perforated tray.

Mesh baskets are great for smaller parts, while a perforated tray may be needed for heavier parts. Remember: the price of an ultrasonic cleaner goes up drastically with tank size. If you have large parts, you can always clean one side, flip it over, then clean the other.

This obviously will take twice as long, but can save you hundreds when purchasing a machine.

Do you plan to clean multiple carburetors at once? This will also require an increase in tank size. It is unwise to jam your cleaning basket full to the brim with delicate carburetor parts, as ultrasonic cleaning does cause a slight vibration which will make your parts rub against each other during cleaning.

There is also the shadowing effect to consider, parts in the middle of the pile will not be cleaned nearly as well as parts on the outside. As far as speed is concerned, this also goes along with how many parts you wish to clean at once.

Most ultrasonic cleaners available to the general public come in three sub-models: mechanical timer only, mechanical timer with heat, and lastly some sort of digital control with heat.

For cleaning carburetors, any type with heat is STRONGLY recommended. Petroleum based soils require heat to clean effectively, and while you could fill your tank with hot water every time, it’s much better to have a constantly heated tank. This will save you both time and money in cleaning chemistry.

Carburetor Cleaning Solutions

Speaking of cleaning chemistry (or “juice” as we call it), you may be wondering just what you put in this thing. The answer is simple: MC-3. MC-3 is a concentrate made specifically for use in ultrasonic cleaners, and for the cleaning of metal parts.

Most ultrasonic cleaning detergents come in a concentrate, and most are for a specific application like metal or circuit board cleaning. Branson’s MC-3 has proven time and again to be a solid cleaner for carburetors.

IMPORTANT SAFETY NOTE!: Never. Ever. Under any circumstances, put anything flammable in an ultrasonic tank. Cavitation can produce microscopic “hot spots” in a liquid, and if one of these spots happens to be near the surface it could produce a flash over!

Cleaning Your Carburetor

The actual cleaning of the carburetor itself in an ultrasonic cleaner is fairly strait forward. First, disassemble your carburetor down to a level where all parts will have access to the water. With an ultrasonic cleaner you may not have to completely take your carburetor apart, but for the best results we suggest you do so. Next, lay your parts inside the parts basket, or however you plan to keep them suspended from the bottom of the tank. Lastly, turn on your unit’s heater, choose your cleaning cycle time, and hit go. It’s that easy!

Tip: Pay attention to how long it takes your parts to get clean with a fresh tank of hot water and detergent. When it starts to take significantly longer to get to that same level of clean, it’s time to change your cleaning solution.

Once your parts are clean, simply drain and dry them as normal. This is the big advantage of ultrasonic cleaning. Instead of hand scrubbing your delicate parts one by one, you can simply clean them all at once, and more thoroughly, in an ultrasonic tank.

For cleaning most smaller carburetors, a small, heated unit such as a Branson 2800 or Crest CP360 will do the job just fine. Both units are 100% professional grade ultrasonic cleaner made for medical, scientific, and industrial applications.

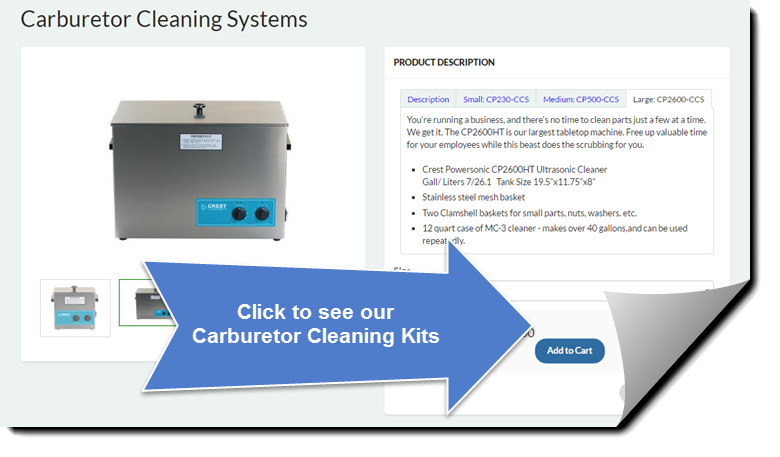

If you have multiple carbs to take care of, or larger units, take a look at our integrated carburetor cleaning systems.

- Tags: Applications

- Last Updated

- David Huckabay

Comments 0